What is a Line Scan Camera?

What are Line Scan Cameras?

Line scan cameras are advanced imaging devices designed to capture images one line at a time. Unlike traditional area scan cameras, which capture a whole frame at once, line scan cameras read images line by line, making them ideal for high-speed and high-resolution applications.

At Process Parameters, our range of industrial cameras features a line scanning mode, a unique selling point that offers comprehensive temperature data analysis and documentation for processes involving moving objects.

Send An EnquiryWhat is Line Scanning?

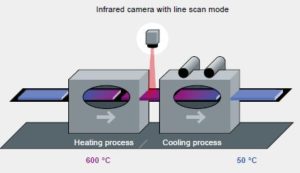

Line scanning is a method used by line scan cameras to capture continuous images of an object or scene. By moving either the camera or the object, the camera captures one line of pixels at a time.

This method is particularly useful for inspecting fast-moving or continuous materials such as textiles, films, or paper, ensuring that every part of the material is thoroughly examined without any gaps.

How Line Scan Cameras Work

Line scan cameras operate by using a single row of pixels (a line sensor) to capture data. As the object or camera moves, each line of pixels is exposed in sequence, creating a complete image over time.

This process allows for extremely high resolutions and fast image acquisition speeds, making line scan cameras perfect for detailed inspections of continuous processes.

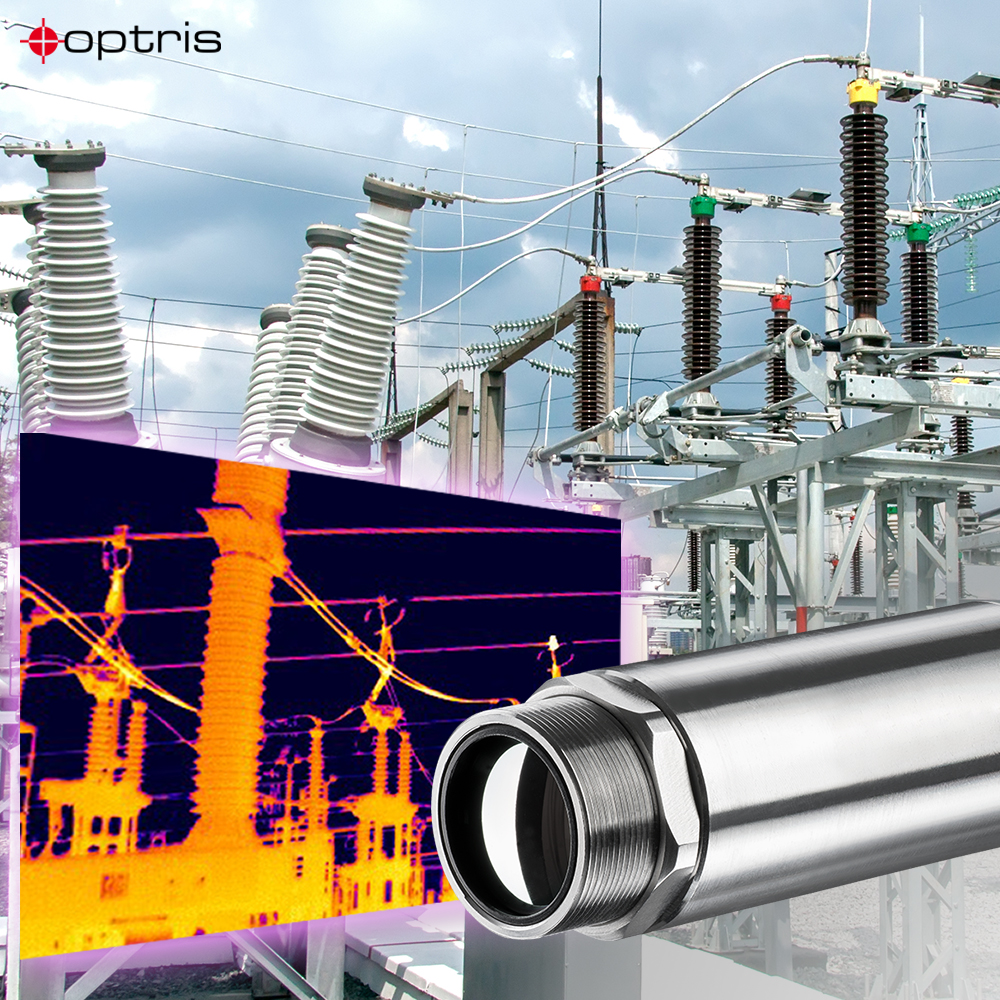

Optris thermal imaging cameras are designed for precisely this type of application. The miniaturised, rugged designs are intended for mounting on industrial machines to provide continuous monitoring of a given process. This could be injection moulding, extrusion, vacuum forming or blown film processing.

There are a few key design features of the Optris thermal imaging camera range that lend themselves to this type of use:

- USB or Ethernet connection to a Windows PC allows the cameras to be very small and low-cost. Mounting the cameras onto machines is easy as they take up very little space and are perfectly capable of handling arduous environments.

- High-speed frame rates of up to 120Hz allow the monitoring of extremely high-speed applications, and with response times of approximately 12 milliseconds we really can capture fast-moving processes, for example, parts being ejected from mould tools.

- High-resolution images allow the temperature measurement of very small objects or parts, often impossible to achieve and often the cause of many moulding quality issues (too hot, too cold, short shot etc.).

Line Scan vs. Area Scan Cameras

While both line scan and area scan cameras serve to capture images, they do so in fundamentally different ways.

Line Scan Cameras:

- Capture images line by line

- Ideal for high-speed and high-resolution applications

- Best for continuous or moving objects

Area Scan Cameras:

- Capture images frame by frame

- Suitable for static or slow-moving objects

- Easier to set up and use for general-purpose imaging

Applications of Line Scan Cameras

Industrial Inspection

Line scan cameras are widely used in industrial inspection to ensure the quality and integrity of products. They are particularly beneficial in manufacturing and quality control, where they can detect defects or inconsistencies in materials and products quickly and accurately.

Use in Manufacturing and Quality Control

In manufacturing, line scan cameras monitor production lines, ensuring that products meet specific standards and identifying defects early in the process. This capability helps reduce waste and improve overall product quality.

Medical Imaging

In the medical field, line scan cameras are used for diagnostic imaging and research. Their ability to capture high-resolution images of tissues and other biological samples makes them invaluable for detailed analysis and accurate diagnostics.

Applications in Diagnostics and Research

Line scan cameras provide precise imaging for various medical applications, from capturing detailed images of tissue samples to monitoring patient conditions in real-time.

Print Inspection

In the printing industry, line scan cameras ensure the quality of printed materials. They check for alignment, colour consistency, and any defects that may occur during the printing process, ensuring that the final product is of the highest quality.

Web Inspection

Web inspection involves monitoring continuous materials such as paper, film, and textiles. Line scan cameras are perfect for this application, providing real-time, high-resolution images that help maintain quality control throughout the production process.

Choosing the Right Line Scan Camera

Factors to Consider: Resolution, Speed, Interface

When selecting a line scan camera, consider factors such as resolution, speed, and interface. Higher resolution cameras provide more detailed images, while faster cameras can handle quicker production lines. The interface should be compatible with your existing systems for seamless integration.

Common Mistakes to Avoid

Avoid common mistakes like overlooking the importance of matching the camera’s speed with the production line speed or ignoring the need for proper lighting to ensure image clarity. Consulting with experts can help you choose the right camera for your specific application.

Installation and Maintenance of Line Scan Cameras

Best Practices for Installation

Proper installation is crucial for optimal performance. Ensure the camera is securely mounted and aligned with the object or production line. Calibrate the camera according to the manufacturer’s instructions to achieve accurate results.

Maintenance Tips to Ensure Longevity

Regular maintenance, such as cleaning the camera lens, checking connections and calibration, will ensure long-term performance. Periodically update the camera software and firmware to benefit from the latest features and improvements.

Industrial Cameras From Process Parameters

Line scan cameras capture images one line at a time, making them ideal for high-speed and high-resolution applications. They are extensively used in various industries for quality control, medical imaging, print inspection, and web inspection.

Line scan cameras are indispensable tools in modern industry, providing the precision and speed needed for detailed inspections and quality control.

Process Parameters is the UK distributor for Optris, a German manufacturer of infrared thermometers and thermal imaging cameras. We have twenty years of experience in this field and can help you achieve the best performance from this type of product.

Our cameras feature advanced line scan software for unparalleled performance and reliability for your temperature monitoring and inspection needs.

Contact us now to discuss your application and find out if thermal imaging can improve your process. Complete our online enquiry form, email sales@processparameters.co.uk or call 01628 778788.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

FAQs About Line Scan Cameras

What industries benefit most from line scan cameras?

Industries such as manufacturing, printing, medical imaging, and web inspection benefit significantly from line scan cameras due to their high-resolution and high-speed imaging capabilities.

How do I choose the right line scan camera for my application?

Consider factors like the required resolution, speed, and compatibility with your existing systems. Consulting with experts and understanding your specific application needs will help you make an informed decision.

What are the limitations of line scan cameras?

Line scan cameras can be more complex to set up and require precise alignment and calibration. They are best suited for continuous or high-speed applications, which may limit their use in certain scenarios.

Related Guides:

- How Do Thermal Imaging Cameras Work?

- Can a Thermal Camera See Through Walls?

- How Does an Infrared Thermometer Work?

- Choosing an Infrared Pyrometer

- What is an Infrared Thermometer?

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- How Accurate Are Infrared Thermometers?

- What is a Pyrometer?

- What is Optical Resolution?