Comparing Contact and Non-Contact Temperature Sensors

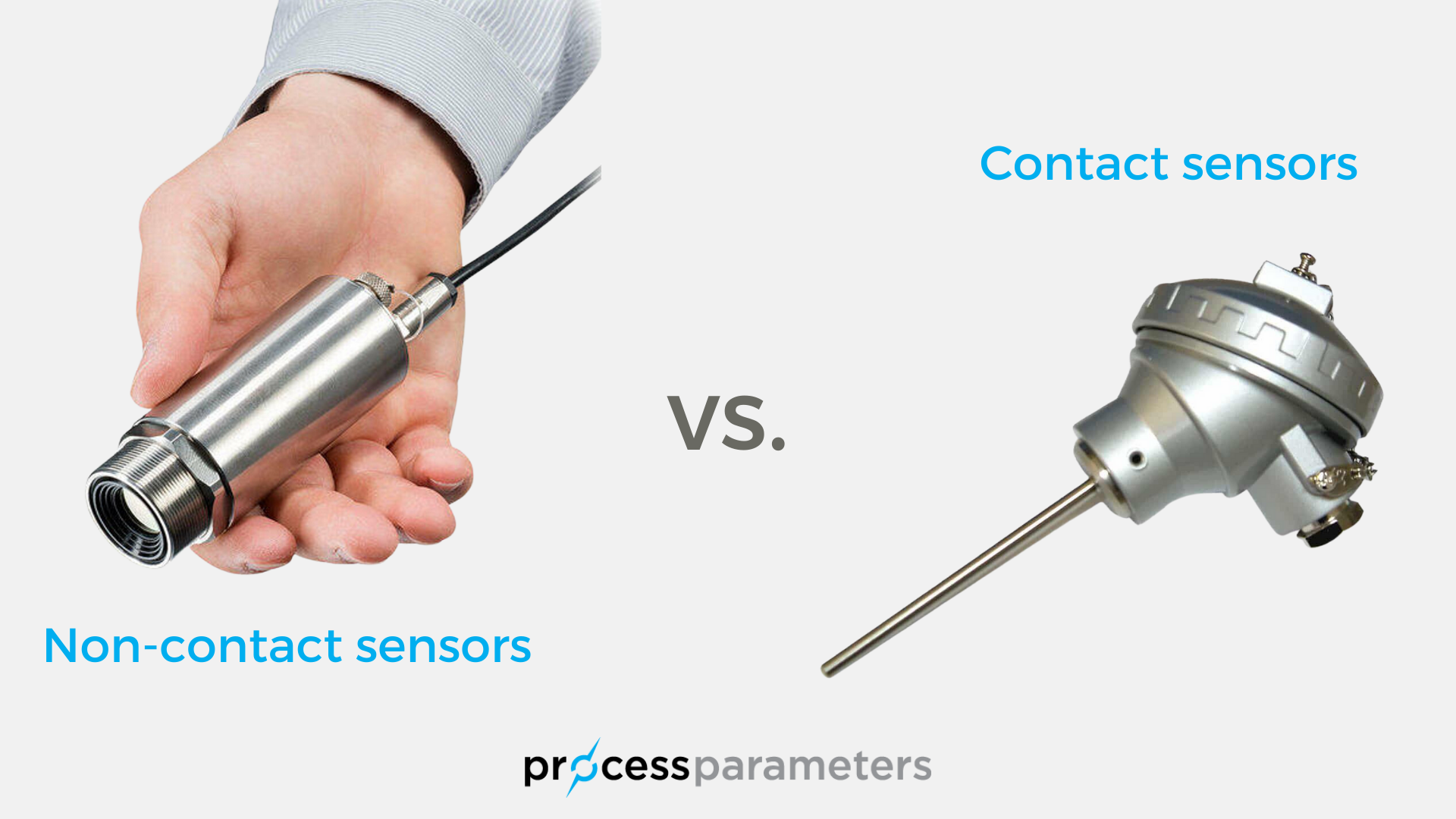

Contact and Non Contact Temperature Sensor Comparison

Temperature sensors are devices that measure the temperature of a given environment, liquid or object. An accurate temperature reading is critical for controlling and maintaining the desired climate in industrial, commercial and residential settings. Temperature sensors can be defined as either contact or non-contact.

In this article, we talk about the difference between contact sensors and non-contact temperature sensors, and the advantages and disadvantages of each type.

How Do Contact Temperature Sensors Work?

Contact temperature sensors measure temperature by coming into direct contact with the object of interest. They are the most common type of temperature sensor and are used in various industrial applications.

Contact sensors work by measuring the heat energy that is transferred from the object to the sensor. The most common types are thermocouples, thermistors, and resistance temperature detectors, which each use different methods to calculate and measure temperature.

Related: What is a Temperature Sensor?

Contact Temperature Sensor Types: Thermocouples, Thermistors, and RTDs

The main difference between thermocouples, thermistors, and RTDs is the type of material used to measure temperature. Thermocouples use two dissimilar metals, thermistors use a semiconductor material, and RTDs use a wire.

- Thermocouples measure the voltage generated by two dissimilar metals when joined together. The difference in temperature between the two different metal wires causes an electrical current to flow, which the thermocouple measures.

- Thermistors measure the resistance of a semiconductor material when exposed to different temperatures. As the temperature of the material changes, so does its electrical resistance, which is then measured by the thermistor.

- Resistance Temperature Detectors (RTDs) measure temperature by measuring the resistance of a wire when exposed to different temperatures. As the temperature of the wire changes, so does its electrical resistance, which is then measured by the RTD.

Process Parameters Ltd is a UK-based manufacturer of industrial contact temperature sensors including Thermocouples, Platinum Resistance Thermometers (also known as RTDs and Pt100) and Thermistor sensors.

We also design and manufacture custom-built contact temperature sensors. If you’re not sure what you need for your application, please get in touch and we can help identify your requirements.

VIEW OUR PT100 SENSORSAdvantages and Disadvantages of Contact Sensors

Contact sensors are often used in situations where accuracy is paramount and contact with the object is possible, such as in medical, pharmaceutical and food processing applications.

The main advantages of contact sensors are their accuracy and precision. Additionally, they are not affected by background radiation and are less likely to be blocked by dust or dirt.

The main disadvantages of contact sensors are the potential logistical limitations of coming into contact with the object of interest. Additionally, they can be damaged, and if they are an internal component of a larger mechanism, fixing and replacing a contact thermal sensor may be expensive and require technical expertise.

What is a Non Contact Temperature Sensor? How Do They Work?

Non-contact temperature sensors measure temperature without coming into contact with the object of interest. They are often referred to as infrared sensors because they use infrared radiation (heat) to measure temperature. Non-contact sensors tend to be quicker than contact sensors and are used in a variety of industrial applications.

Non-contact temperature sensors work by measuring the amount of infrared radiation emitted by an object. Non-contact sensors are often used in situations where contact with the object is not possible, such as in hazardous environments.

Non Contact Temperature Sensor Types

The different types of non-contact temperature sensors include thermal sensors, infrared thermometers, pyrometers, and thermographic cameras.

- Infrared thermometers measure the temperature of an object by detecting and measuring the heat energy, also known as infrared, emitted from the object.

- Pyrometers measure the temperature of an object by detecting and measuring the infrared radiation emitted from the object.

- Thermographic cameras measure the temperature of an object by detecting and analysing the infrared radiation given off by the object.

We are the leading UK distributor for Optris, a manufacturer of infrared thermometers and thermal imaging cameras for applications such as metals, plastics and glass. Contact our team to discuss your application and find out how a non-contact temperature sensor can improve your process.

VIEW OUR IR CAMERASAdvantages and Disadvantages of Non-Contact Sensors

The main advantages of non-contact sensors are their accuracy, speed, and versatility. They can measure temperature from a distance, making them ideal for hazardous environments and for measuring extremely high temperatures that would be impossible to record with contact-type sensors. Additionally, they are capable of measuring temperature from a wide range of objects, including liquids, solids and gases.

The main disadvantage of non-contact sensors is that they aren’t as precise as contact sensors. Additionally, they are subject to errors due to background radiation and can be blocked by water droplets, dust or dirt.

Comparing Contact Sensors and Non-Contact Sensors

In conclusion, a sensor for temperature is used to accurately measure the temperature of objects, liquids and environments in industrial, commercial, and residential settings. There are two main types of temperature sensors: contact and non-contact.

Contact sensors measure temperature by coming into direct contact with the object, while non-contact sensors measure temperature from a distance using infrared radiation. Both types of sensors have their advantages and disadvantages, which may depend on the application and environment.

Speak with our experts for tailored temperature sensor advice.

If you have any questions, please do not hesitate to contact the team at Process Parameters. Call us at 01628 778688 or email us here.

Contact and Non Contact Sensors From Process Parameters

We offer a wide range of temperature sensors for industrial applications. We manufacture both contact and non-contact temperature sensors that are designed to provide accurate and reliable readings in a variety of different environments.

Our contact sensors include thermocouples, resistance temperature detectors (RTDs) and thermistors. Our non-contact sensors include infrared thermometers, pyrometers, and thermographic cameras.

With our high-quality products and reliable customer service, we are a trusted provider of temperature measurement solutions.

Send An EnquiryFAQs

What are examples of contact temperature sensors?

Examples of contact temperature sensors include thermocouples, RTDs, and thermistors, often featuring a stainless steel housing for durability. These sensors require physical contact to measure temperature accurately.

What is the difference between contact and non-contact temperature sensor?

Contact temperature sensors, like RTDs and thermistors, need physical touch to measure temperature, while non-contact sensors, such as IR thermometers, use infrared technology to measure heat from a distance, without direct contact.

What are the two most commonly used contact temperature sensors in the industry?

The two most commonly used contact temperature sensors in the industry are RTDs and thermistors, valued for their accuracy and reliability in various applications, including those requiring water cooling or a cooling jacket.

What is a contact-type sensor?

A contact-type sensor is a device that must physically touch the object being measured to accurately capture the temperature, often featuring a compact design for easy integration with other equipment and accessories.

What are examples of non-contact temperature sensors?

Examples of non-contact temperature sensors include IR thermometers and pyrometers, which use infrared technology to measure temperature remotely, making them ideal for high-temperature or hard-to-reach areas without the need for physical contact.

How effective are non-contact thermometers?

Non-contact thermometers, like IR temperature sensors, are highly effective in industrial applications due to their ability to measure temperatures from a distance. They are commonly used in production line quality control, power plant maintenance, and safety monitoring, offering a digital output for easy interface with other systems.

Related Articles:

- What Is A Temperature Sensor?

- How To Check if You Have a Faulty Temperature Sensor

- What is an RTD Sensor?

- What is a Temperature Transmitter?

- How Does a Thermal Imaging Camera Work?

- Choosing an Infrared Pyrometer

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- What is a Thermocouple?

- What is a Pyrometer?

- Pt100 Wiring Methods – 2, 3 or 4 wire?

- Guide to Industrial Temperature Sensor Devices

- What is a Pt100 Sensor Working Principle?

- Pt100 Temperature Sensor Specification