Thermocouples are a type of sensor used for the measurement of temperature. Thermocouples use the Seebeck effect, discovered by Thomas Johann Seebeck in the early 1800s. He was able to prove that if two dissimilar electrical conductors have a temperature differential across them, then a voltage difference is produced.

How Thermocouples work

So how does a thermocouple work? The voltages generated are extremely small, generally only a few microvolts per degree of temperature difference. Through the development of particular alloy and conductor combinations, these voltages have been tuned to the needs of industrial instrumentation to both maximise the voltage change per degree change of temperature and also to provide the greatest linearity possible.

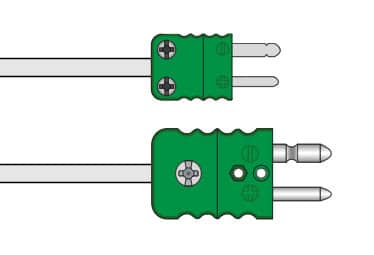

In an industrial application the thermocouple probe or sensor will have a thermocouple junction. This is the temperature-sensitive part of the product and this should be placed at the position where you wish to measure temperature. This junction can be built into a variety of different designs to enable to the measurement of semi-solid, liquid, gas or surface temperatures. The thermocouple probe will generally have a cable which is either wired or plugged into an electronic instrument which will then convert the voltage output from the thermocouple into a temperature value.

Thermocouples are rugged sensors well known for being versatile and suitable for a huge range of applications. Due to the simplicity of the design, simply two wires joined together, thermocouples are suitable in processes where shock and vibration are present. They are also capable of withstanding very wide ranges of temperature. Depending on the thermocouple type and construction the range can extend down to -200°C and up to over 2000°C.

The versatility of thermocouples is further extended by the ability of thermocouple manufacturers such as us to build a very wide range of model types to suit almost any application. They can be mounted in very small housings to monitor bearings and other fast response processes; mounted in handheld probe designs for the food industry; built into high-pressure housings for the plastics extrusion market and made with ceramic components for the heat treatment and furnace industry. Thermocouples are the most numerous of all temperature sensors used today due to their flexibility, resilience and relatively low cost.