Thermistors vs Thermocouples: Choosing the Right Sensor

NTC Thermistors vs Thermocouples

When it comes to measuring temperature, two of the most common sensor types are thermistors and thermocouples. Both have their unique characteristics and are widely used in various applications, from industrial automation to consumer electronics.

Whether you’re monitoring the temperature of your home appliances or managing temperature in an industrial setting, choosing the right sensor is essential for accurate and reliable results.

In this guide, we’ll discuss the key differences between thermistors and thermocouples to help you choose the appropriate temperature sensor for your needs.

Key Highlights

- Thermistors and thermocouples are both temperature-sensing devices, but they work on different principles.

- Thermistors use resistance to measure temperature, while thermocouples use voltage.

- Thermistors are more sensitive and can detect small temperature changes, while thermocouples have a wider temperature range.

- When choosing between thermistors and thermocouples, it’s important to consider factors like temperature range, accuracy, and stability.

- Thermistors are often used in domestic appliances, while thermocouples are commonly used in industrial applications.

- Both thermistors and thermocouples have their pros and cons, so it’s important to choose the right one for your specific application.

What is a Thermistor? Highly Sensitive and Versatile

Thermistors are temperature-sensitive resistors that rely on the principle of changing resistance with temperature. They work on the principle of varying electrical resistance in response to temperature changes, with the resistance decreasing as the temperature increases.

They come in two main types: negative temperature coefficient (NTC) and positive temperature coefficient (PTC) thermistors. NTC thermistors, which are the most common, exhibit a decrease in resistance as the temperature increases, while PTC thermistors show an increase in resistance with rising temperatures.

Thermistors offer a wide range of applications due to their high sensitivity and accuracy. They are used in industries like automotive, medical, and HVAC systems for temperature measurement and control.

Related: What is a thermistor?

Types of Thermistors and Their Uses

Thermistors come in various types, each with its unique characteristics and applications. Here are some common types of thermistors and their uses:

- NTC Thermistors: Negative temperature coefficient thermistors have a decrease in resistance as temperature increases. They are commonly used in applications such as temperature control systems, electronic circuits, and automotive industry.

- PTC Thermistors: Positive temperature coefficient thermistors have an increase in resistance with temperature. They are used in applications such as overcurrent protection, motor starting circuits, and temperature compensation.

- Glass Thermistors: These thermistors are made of glass materials and offer high stability and accuracy. They are used in applications that require precise temperature measurement, such as medical devices and laboratory equipment.

- Bead Thermistors: These thermistors are small in size and are often used for point temperature measurement in various applications.

Data logger with thermistor probe

At Process Parameters, we supply data loggers with thermistor probes. View some of our thermistor data logger products here, or contact us if you’re not sure which device is best for your application.

Contact UsKey Benefits of Thermistors

- High sensitivity: Thermistors can detect small temperature changes with high accuracy, making them suitable for precise temperature monitoring and control applications.

- Wide temperature range: Depending on the specific type, thermistors can operate across a broad temperature range, from cryogenic temperatures to several hundred degrees Celsius.

- Compact size: Thermistors are generally small in size, which allows for easy integration into various devices and systems.

- Cost-effective: Thermistors are generally less expensive than other temperature sensor types, making them a budget-friendly option.

What is a Thermocouple? Robust and Versatile

Thermocouples, on the other hand, rely on the thermoelectric effect, which generates a voltage difference when two dissimilar metals are joined and exposed to different temperatures.

This voltage difference can be correlated to the temperature difference between the two junctions.

Thermocouples are widely used in various industries and applications, including furnaces, ovens, flue gas sensing, and temperature measurement in high-temperature environments. They are known for their durability, wide temperature range, and quick response time.

Related: What is a thermocouple?

Different Thermocouple Types and Their Applications

There are several types of thermocouples available, each with its unique characteristics and temperature range. Here are some common types of thermocouples and their applications:

- Type K Thermocouple: This type of thermocouple is made of chromel and alumel and is one of the most widely used thermocouples. It has a temperature range of -200°C to 1,372°C and is suitable for various applications, including industrial processes, HVAC systems, and power plants.

- Type J Thermocouple: This thermocouple is made of iron and constantan and has a temperature range of -40°C to 750°C. It is commonly used in applications such as food processing, ovens, and furnaces.

- Type T Thermocouple: Made of copper and constantan, this thermocouple has a temperature range of -200°C to 350°C. It is often used in low-temperature applications, such as refrigeration and cryogenics.

- Type E Thermocouple: This thermocouple is made of chromel and constantan and has a temperature range of -200°C to 900°C. It is commonly used in applications such as automotive, petrochemical, and aerospace industries.

Thermocouple sensors are available in various sizes and configurations to suit different temperature ranges and applications.

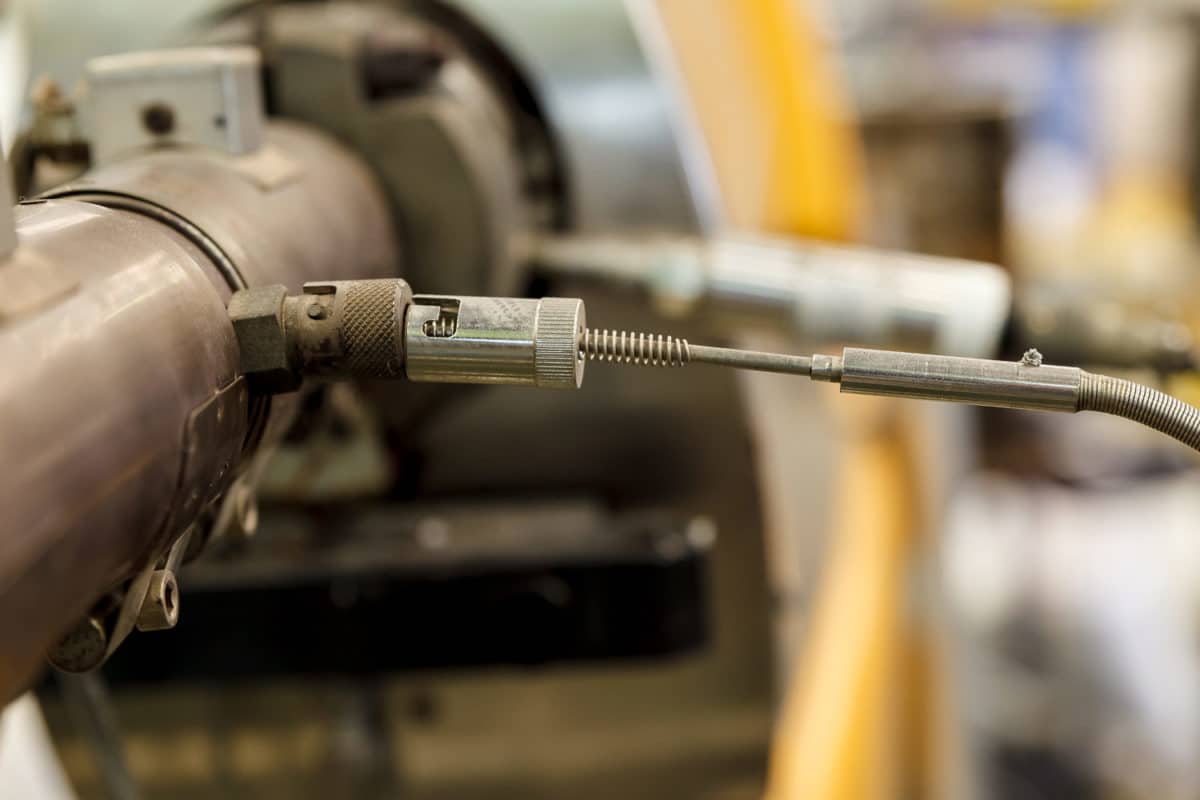

Type K thermocouple manufactured by Process Parameters

At Process Parameters, we design and manufacture robust, fast-responding custom thermocouple probes and thermocouple temperature sensors in the UK.

If you’re not sure what you need, please get in touch with our experts and we can help identify your requirements.

Send An EnquiryThermocouple Sensors & Probes

Temperature Probes & Sensors

Thermocouple Sensors & Probes

Thermocouple for Ambient Air Temperature Measurement Sensor – PPL10-T

Temperature Probes & Sensors

Key Benefits of Thermocouples

- Wide temperature range: Thermocouples can operate over an extensive temperature range, from as low as -200°C to as high as 2,000°C, making them suitable for a variety of high-temperature applications.

- Rugged construction: Thermocouples are generally more durable and can withstand harsh environments, such as high-vibration or corrosive conditions, better than other temperature sensor types.

- Self-powered: Thermocouples generate their own voltage signal, eliminating the need for an external power source, which can be advantageous in remote or inaccessible locations.

- Versatility: Thermocouples come in a wide variety of types, each with different temperature ranges and sensitivities, allowing for flexibility in sensor selection.

Choosing Between Thermistors and Thermocouples

When selecting between thermistors and thermocouples, consider the following factors:

- Temperature range: If you need to measure temperatures outside the typical range of thermistors (typically -50°C to 300°C), thermocouples may be a better choice.

- Accuracy and sensitivity: Thermistors generally offer higher accuracy and sensitivity, making them better suited for applications that require precise temperature monitoring.

- Environmental conditions: If the application involves harsh or challenging environments, thermocouples may be more resilient and reliable.

- Cost and complexity: Thermistors are generally more cost-effective and easier to integrate, while thermocouples may require additional signal conditioning and wiring.

- Standardisation: Unlike thermocouples and RTDs, thermistors do not comply with national or international standards, which means they are not interchangeable across different manufacturers. The thermistor manufacturers drive the designs and specifications, potentially locking customers into a specific type of sensor if they choose a particular instrument manufacturer, especially in lower-temperature applications like the food industry.

Thermistors vs Thermocouples in Industrial Use

Both thermistors and thermocouples have their place in industrial applications, providing temperature measurement and control solutions for different requirements.

Thermistors are commonly used in industrial settings where precise temperature measurement is crucial. They are used in a wide range of industries, including automotive, medical, and HVAC systems. Thermistors offer high sensitivity and accuracy, making them ideal for applications that require precise temperature control.

Thermocouples, on the other hand, are widely used in industrial applications that involve high-temperature environments. They are known for their durability and stability, making them suitable for applications such as furnace monitoring, power plants, and industrial processes that require temperature measurement in extreme conditions.

Conclusion

Choosing between thermistors and thermocouples depends on your specific temperature measurement needs.

Both technologies have their pros and cons, so it’s essential to weigh them carefully.

Thermistors offer advantages in certain applications, while thermocouples excel in others. Consider your application requirements and environmental factors when making your decision.

For further guidance on selecting the right temperature sensor for your application, feel free to reach out to our experts for personalised assistance.

Please email us at sales@processparameters.co.uk or call 01628 778788.

Send An EnquiryFAQs

Why are thermistors better than thermocouples?

Thermistors are generally better than thermocouples in terms of higher sensitivity, smaller size, and lower cost. They can detect small temperature changes with high accuracy and are more suitable for precise temperature monitoring applications. Thermistors also have a wider operating temperature range compared to some thermocouple types.

What is the difference between a thermistor and a thermometer?

The main difference between a thermistor and a thermometer is that a thermistor is a temperature-sensitive resistor that changes its resistance with temperature, while a thermometer is a device that directly measures and displays the temperature. Thermistors are components used in temperature measurement, while thermometers are the complete instruments designed to measure and indicate temperature.

What is the difference between thermistor and thermocouple and RTD?

The key differences are:

Thermistor: Temperature-sensitive resistor with high sensitivity and wide temperature range, but limited to lower temperatures compared to other options.

Thermocouple: Generates a voltage based on temperature difference between two junctions, can measure very high temperatures, but less accurate than thermistors.

RTD (Resistance Temperature Detector): Resistance-based sensor with higher accuracy and stability than thermistors, suitable for a wide temperature range.

What is a temperature sensor probe?

A temperature sensor is a device that measures and converts temperature variations into an electrical signal, such as output voltage or resistance changes. Key characteristics and uses of temperature sensors include:

- Different metals used in thermocouples generate an output voltage based on temperature differences between the hot and cold junctions.

- Resistance thermometers (RTDs) using materials like platinum have a wide temperature range and fast response, suitable for monitoring higher temperatures.

- Thermal resistors like thermistors exhibit resistance changes with temperature, providing a sensitive electrical signal, but have a more limited temperature range, typically around room temperature.

- Temperature sensors with probes are used in a variety of applications, from fire detectors to industrial process control, to measure and convert thermal variations into an electrical signal for monitoring and control.

- Proper calibration is essential to ensure accuracy, as factors like lead resistance can impact the sensor’s output, especially at lower temperature accuracies.

Can thermistors and thermocouples be used interchangeably?

Thermistors vs thermocouples work on different principles and have different characteristics. They cannot be used interchangeably as temperature sensors. Thermistors rely on resistance changes, while thermocouples generate voltage. The choice depends on the specific application requirements.

Related Guides:

- How Does a Thermocouple Work?

- What Does a Thermistor Do?

- Advantages and Disadvantages of Thermocouples

- What is a Temperature Transmitter?

- Comparing Contact and Non-Contact Temperature Sensors

- What Is A Temperature Sensor?

- What is a Thermistor?

- What is Temperature?

- What Are Type K Thermocouples?

- Differences Between J and K Type Thermocouples

- What is an RTD?

- RTD vs. Thermocouple: Choosing the Right Temperature Sensor