What is a Machine Vision Camera?

A Guide to Machine Vision Cameras

Machine vision cameras refer to the technology that allows automated equipment to “see” and make decisions based on captured images. They’re used for inspection, process control, and robot guidance in industrial environments.

Temperature measurement is an important application of some industrial machine vision systems, as monitoring temperature is critical for product quality and process optimisation.

At Process Parameters, we are experts in temperature measurement for industrial applications. Our friendly team is available to discuss your requirements and see how our products can benefit your processes.

Send An EnquiryThis article will cover all of the key questions around machine vision, including common uses and benefits of the technology.

Let’s dive in.

What is Machine Vision?

Machine vision uses cameras, lighting, and image processing to perform measurements, inspections, counts, and quality checks automatically with precision. It mimics human vision and judgment using computer hardware and software.

How Does a Machine Vision System Work?

A machine vision system captures images of objects, transfers them to a computer, and uses specialised software to extract meaningful information from the images, such as dimensions, defects, temperature, counting units, and characters.

This data allows automatically controlled manufacturing processes and quality monitoring.

What is a Machine Vision Camera?

What Are Machine Vision Cameras Used For?

Machine vision cameras are used for automated inspection, alignment, measurement, flaw detection, character recognition, barcode reading and more in industrial environments.

They provide rapid, precise quality control and process data that is not easily captured manually.

Machine vision cameras improve quality control processes and enhance manufacturing efficiency. They contribute to waste reduction, defect prevention and overall optimisation.

What Industries Use Machine Vision?

Machine vision is used across many industries including automotive, pharmaceutical, electronics, food and beverage, packaging and logistics. Any manufacturing process that requires high speed, accuracy and repeatability can benefit from machine vision.

What are the Benefits of Machine Vision in Manufacturing?

Machine vision cameras are essential for enhancing quality control processes through task automation, improved precision, repeatability, and increased speed and throughput.

These cameras capture high-resolution images or video streams of products and components, which are then analysed using advanced computer vision algorithms.

This results in quicker and more precise defect detection, gaging, guidance, measurements, and verification compared to manual inspection methods.

Some of the key benefits of machine vision cameras include:

- Increased quality control and fewer errors

- Improved production speed, efficiency and volumes

- Reduced waste and higher yields

- Enhanced traceability and compliance

- More flexible and optimised processes

- Uninterrupted 24/7 operation

The Different Types of Machine Vision Camera Formats

Different camera types suit different machine vision applications. Common formats include digital single lens reflex (DSLR), charge-coupled device (CCD), complementary metal oxide semiconductor (CMOS) and thermal cameras.

Thermal Cameras and Machine Vision

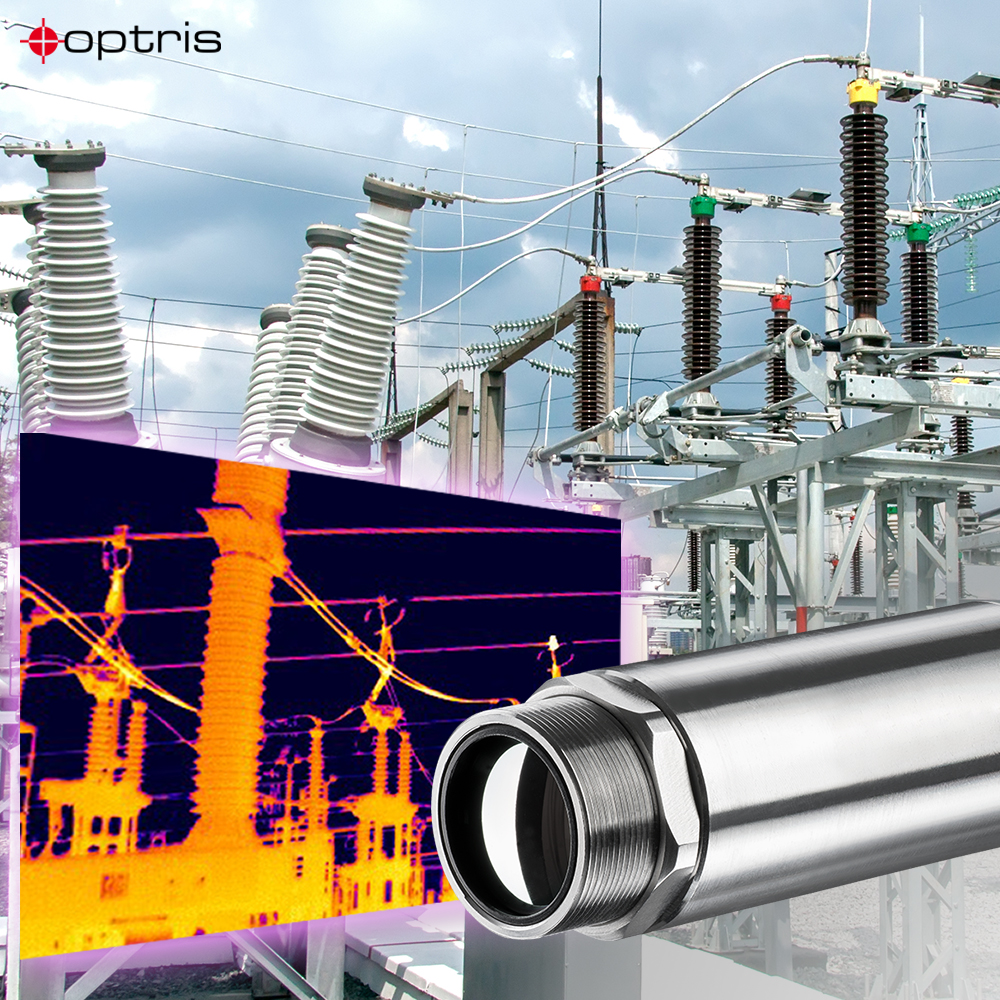

Temperature is a critical parameter across industries from metal manufacturing to food processing. Machine vision thermal cameras allow non-contact temperature measurement. This data enables monitoring that temperatures remain within specified ranges to meet quality standards.

Thermal cameras detect infrared radiation to visualise and measure surface temperatures without contact. In machine vision, they enable temperature analysis for monitoring processes and identifying issues.

Thermal imaging provides heat mapping to pinpoint excessive temperatures, detect equipment failures, and prevent damage.

By capturing detailed thermal data, machine vision thermal cameras improve safety, efficiency, and performance across applications like building inspections, electrical inspections, manufacturing, and surveillance.

Thermal machine vision applications include monitoring flows, bearings, electrical systems and more to optimise equipment health.

Questions? Speak to one of our experts about your temperature measurement requirements.

Our engineers can work with you to select the right infrared thermometer or thermal camera for your facility. We also develop and manufacture custom designs of temperature sensors.

View Thermal CamerasIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Components of Machine Vision Systems

The core components of a machine vision system work together to capture, process and analyse image data for industrial applications. These include:

Cameras

Contain sensors that transform light into digital images that are transmitted to the processing equipment. The right camera is selected based on inspection requirements.

Lens

Lenses focus light onto the camera sensor to produce sharp, high-contrast images. They concentrate and control light.

Lights

Carefully controlled lighting highlights features of interest and reduces environmental interference. Proper illumination ensures cameras can clearly see objects being inspected.

Unit for image processing

Processing units analyse images and extract information using specialised algorithms and software tools. They interpret image data and output actionable results.

The seamless integration of these vital elements enables machine vision platforms to perform automated optical inspections, measure parts, guide processes, and make instant decisions to drive quality and productivity.

Industrial Cameras from Process Parameters

Interested in purchasing a machine vision camera for your business? At Process Parameters, we are a leading distributor of Optris thermal imaging cameras and infrared thermometers supplying to companies within the UK, Ireland and worldwide.

Businesses can expand their scanning capabilities and easily set up, deploy, and run vision applications using cutting-edge smart cameras and powerful software tools.

View our range of IR cameras or contact us for a free quote.

Send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryGeneral Purpose IR Thermometers

General Purpose IR Thermometers

General Purpose IR Thermometers

Machine Vision FAQs

What is the Difference Between Machine Vision and Computer Vision?

Machine vision refers to dedicated systems for industrial automation tasks while computer vision is a field of artificial intelligence focused on enabling computers to interpret and understand digital images and videos.

What is an Example of Machine Vision?

Common machine vision applications include checking bottle label accuracy, monitoring products on a packaging line, reading serial numbers for traceability, inspecting surfaces for defects, and guiding robots.

Can You Use Any Camera for Machine Vision?

Specialised machine vision cameras are designed for the rugged industrial environments and performance requirements that automated inspection and guidance processes demand. They provide exceptionally high-quality images at fast capture rates with tools tailored for machine vision like precise camera control and external triggering.

How Is a Machine Vision Camera Different from a Normal Camera?

Machine vision cameras are high-precision with advanced sensors and global shutters, enabling undistorted images of fast-moving objects. They also offer faster frame rates, synchronisation tools, and optics and lighting control capabilities beyond consumer cameras. The images feed into specialised software rather than human viewing.

Related Knowledge Guides:

- How to Improve Manufacturing with an Industrial Camera

- Can a Thermal Camera See Through Walls?

- How Does a Thermal Imaging Camera Work?

- Benefits of Industrial Inspection and Quality Control Cameras

- How Accurate are Infrared Thermometers?

- Using a Thermal Camera to Detect Heat Loss

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- What is Thermal Scanning?

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Pyrometer or IR Camera?