What is Thermal Scanning and Screening?

Everything You Need to Know About Thermal Scanning

Thermal cameras quickly emerged as invaluable tools with a multitude of applications, but what is thermal scanning and screening? The innovative process uses infrared cameras to detect heat emitted from objects, unlocking a wealth of information indetectable to the human eye.

From identifying individuals and animals in low-light conditions to safeguarding buildings, machinery, and infrastructure against potential issues, thermal scanning has become a versatile, non-invasive, and non-destructive means of gathering data from infrared radiation.

In this article, we look at the intricacies of thermal imaging, its applications across many industries, as well as advantages and limitations.

Process Parameters Ltd is the UK distributor for Optris, a German manufacturer of infrared thermometers and thermal imaging cameras. We have twenty years of experience in this field and can help you achieve the best performance from this type of product.

Contact us to discuss whether thermal imaging could improve your process.

What is Thermal Scanning?

Thermal scanning and screening involve the detection of heat emissions from objects using infrared cameras. Its applications extend to identifying individuals or animals in low-light conditions and uncovering potential issues within structures, machinery, and various infrastructures.

The image below shows a thermal imaging camera being used for hot spot detection at a glass bottle production.

How Does Thermal Scanning Work?

The infrared cameras used in thermal screening measure the temperature of objects by detecting the amount of infrared radiation they emit. Infrared radiation is a type of electromagnetic radiation that is invisible to the naked eye but can be detected by infrared cameras.

Thermal cameras can then convert the radiation levels into an image that can be seen on a screen. The image shows the relative temperatures of different objects, with warmer objects appearing brighter and cooler objects appearing darker.

More information on How Does a Thermal Imaging Camera Work?

What Are The Different Types of Thermal Screening and Scanning Devices?

Thermal scanners generate a real-time digital image of heat emitted from objects through the detection of infrared radiation. As well as built-in scanners, a wide range of portable thermal scanners have also been developed, with varying resolutions and price points.

For example, thermal scanners are currently available as handheld video cameras, handheld scopes, road vehicle and vessel-mounted scanners, as well as drone and manned aircraft-mounted cameras.

Contact our team to discuss your needs and find out how a thermal imaging camera can improve your process, or view our range of thermal cameras for a variety of industries below.

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Thermal Scanning and Screening: Industries and Applications

- Security and surveillance

Thermal scanning can detect people and animals in the dark, even if they are trying to camouflage themselves.

- Building inspection

Thermal scanning can identify areas of heat loss in buildings, as well as to detect potential problems with electrical wiring and HVAC systems. This can help building owners save money on their energy bills and avoid costly repairs.

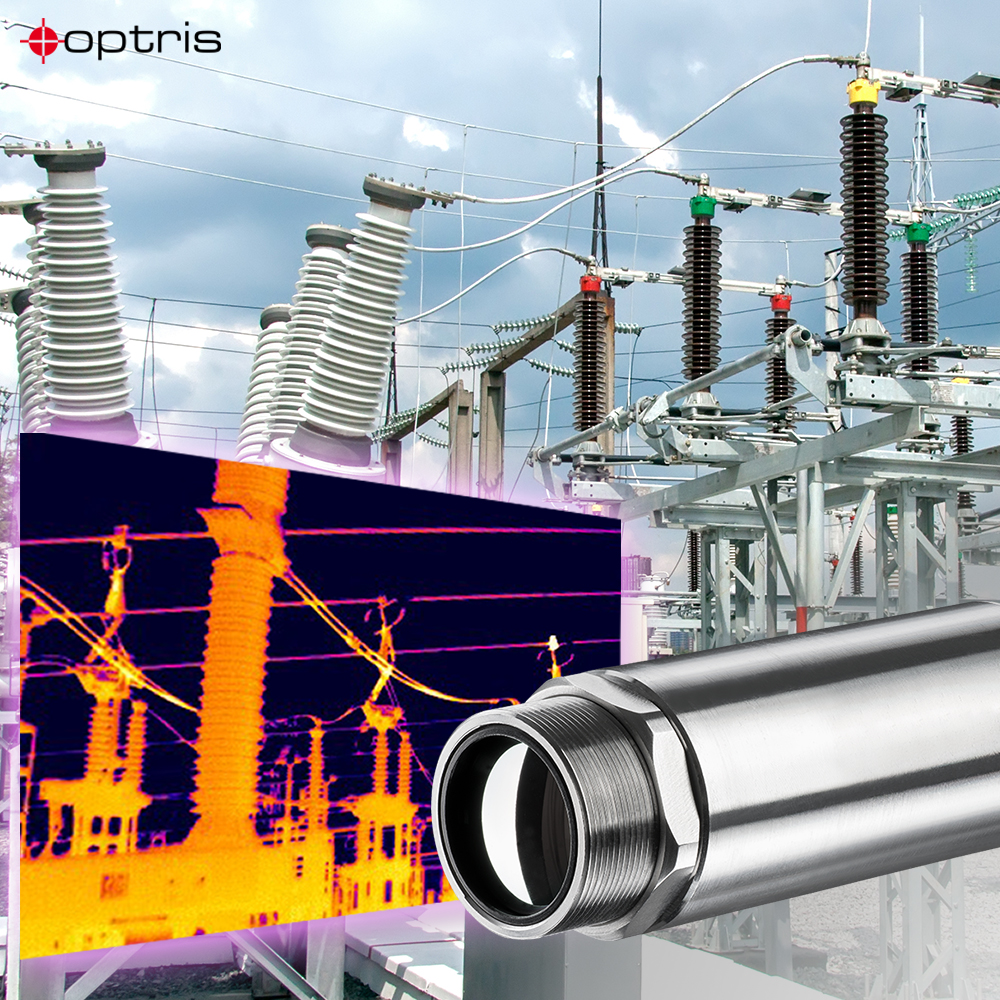

- Electrical inspection

Thermal scanning can identify hot spots in electrical systems, which can indicate potential problems such as loose connections or overloaded circuits. This can help prevent power outages and other electrical hazards.

- Manufacturing quality control

Thermal scanning can identify defects in manufactured products, such as cracks and voids. This can help manufacturers improve the quality of their products and reduce waste.

- Animal husbandry

Monitoring the health of livestock and to detect potential problems such as inflammation or infection. This can help farmers improve the health and welfare of their animals.

- Pest control

Thermal cameras can be used to detect pests such as termites and bed bugs. This can help pest control companies identify and eliminate pests quickly and effectively.

- Firefighting

Thermal cameras can be used to identify hot spots in fires and to locate victims.

- Environmental monitoring

Monitor for environmental hazards such as pollution and wildfires. This can help environmental agencies protect the public and the environment.

- Public health and safety

Detecting people with fevers, which can be a symptom of infectious diseases such as COVID-19.

How Can a Thermal Imaging Camera Become Part of Your Process?

Advantages and Disadvantages of Thermal Scanning

What Are The Benefits of Using Thermal Imaging?

Thermal screening and scanning has a number of benefits, including:

- Non-invasive and non-destructive technology, ensuring minimal interference.

- Effective in low-light or no-light conditions, providing visibility where the human eye falters.

- Capable of long-range identification of individuals and animals.

- Detects potential issues in structures, machinery, and infrastructure.

- Enhances efficiency and safety in measurement processes.

- Facilitates cost-saving through regular predictive maintenance, reducing downtime, power outages, production losses, and fire risks.

- Delivers swift and precise measurements for objects in challenging-to-reach locations, such as high-altitude power lines.

- Enables highly accurate temperature assessments of machinery from a safe distance, even while machines remain in operation.

- Identifies air leakages, documents irregular heat distribution, and pinpoints potential insulation flaws.

5 Benefits of Thermal Imaging Cameras

What Are The Disadvantages of Thermal Scanners?

- Initial investment costs for thermal imaging products are notably high.

- Interpretation of images becomes challenging when dealing with objects exhibiting unpredictable temperature fluctuations.

- Precise temperature measurements can be compromised by variations in emissivity and surface reflections.

- Thermal imaging cameras are unsuitable for underwater object examination.

- The accuracy of most thermal imaging cameras typically falls within the range of +/-2% or worse for temperature measurement, making them less accurate than contact methods.

- Thermal imaging cameras are incapable of penetrating glass surfaces, as thermal energy can be reflected by shiny materials. Moreover, they lack the capability to see through walls.

What are Some Future Trends in Thermal Screening and Scanning?

Thermal screening and scanning technology is constantly evolving, and there are a number of trends that are likely to shape the future of this industry. These trends include:

- The development of more affordable and portable thermal imaging devices.

- The integration of thermal imaging into other technologies, such as drones and robots.

- The use of artificial intelligence (AI) to improve the accuracy and speed of thermal image analysis.

Summary of What is Thermal Scanning

Thermal scanning, the use of infrared cameras to detect heat emissions, is a rapidly evolving technology. One of the key advantages is its non-invasive and non-destructive nature.

This makes it ideal for a variety of applications where traditional methods may be impractical or disruptive. For example, a thermal scanner can be used to identify areas of heat loss in buildings without the need to drill holes or damage walls.

It’s also important to note that the technology also has some limitations. One limitation is the initial cost of thermal cameras. However, prices have been falling in recent years, and more affordable options are now available.

Thermal scanning is a powerful and versatile technology, and as the technology continues to evolve and become more affordable and accessible, we can expect to see thermal scanning play an increasingly important role in our lives.

For more information on any thermal imagers, or for further advice, please contact one of our support team who will be happy to assist you.

Please send us an email at sales@processparameters.co.uk, call 01628 778788, or complete our online enquiry form.

Send An EnquiryIndustrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Optris PI400i/PI450i High Resolution Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

Industrial Thermal Imaging Cameras

FAQs

Why do electricians use thermal imaging?

Thermal screening allows electricians to monitor wire and component temperature in a non-invasive and non-destructive way, which keeps them safe, reduces replacements, and reduces damage.

Why is thermal scanning important?

Thermal scanning is an important technology with a wide range of applications. It is a non-invasive, non-destructive, and versatile way to detect heat emitted from objects. This makes it a valuable tool for a variety of industries and applications.

What is thermal scanning and screening of electrical systems?

Monitoring changes in temperature along power lines or within components. For example, a power company uses thermal cameras to inspect electrical lines for hot spots, which can help them prevent power outages.

Related Articles:

- How Does a Thermal Imaging Camera Work?

- How Accurate are Infrared Thermometers?

- Can a Thermal Camera See Through Walls?

- How Does an Infrared Thermometer Work?

- Choosing an Infrared Pyrometer

- What is a Pyrometer?

- Why is a Pin Sharp Thermal Image Important?

- How Can a Thermal Imaging Camera Become Part of Your Process?

- Can You Improve Your Thermal Efficiency With Imaging Cameras?

- Pyrometer or IR Camera?